Biological processes are the core of the treatment process in most cases. In this way, organic matter and nitrogen are eliminated and released as CO2 and N2 gases. The Berghof external MBR entails numerous advantages over the conventional biological treatments and the submerged MBRs, as enumerated below:

Highly efficient biological treatment: the operation at high MLSS concentration (12 – 15 g/L, up to 30 g/L) provides long sludge ages, which intensifies the acclimatization of biomass and its performance even with the most complex leachates. Slowly biodegradable organics and nitrogen are removed very efficiently.

Quick and flexible implementation. Filtration systems based on Berghof membranes are 100% modular and plug & play. In addition, the systems can be easily containerized. Retrofitting and upgrading conventional leachate treatment plants is simple and fast. Future expansion of the plant can be done very easily.

Due to the higher biomass concentration in the bioreactor and the operation with high permeate flux, that minimizes the installed membrane area.

The high modularity of the UF systems allows adapting the skid’s location to the available space or installing them inside a standard container.

After treatment with tubular ultrafiltration membranes the leachate effluent is free of solids, without turbidity, and low SDI . The effluent from the membrane bioreactor can be directly fed to NF or RO when color or salts need to be eliminated for discharge in natural water bodies.

Our external tubular membranes are less affected by leachate variabilities or the presence of foulant compounds. These are known to affect the performance of submerged membranes. Moreover, fouling control by adaptive hydrodynamic conditions and backwash/CEB can be easily implemented, in order to achieve the most stable operation even under the most challenging conditions.

Ease of maintenance. The external crossflow filtration circuit can be easily isolated for any maintenance operation with minimum system downtime. Berghof membranes are easily accessible, robust, and less susceptible to breakage. Resulting in a long membrane lifespan and an easy-to-use system.

The MBR process provides the highest possible levels of organic removal, with essentially zero suspended solids in the effluent and excellent nitrification and de-nitrification.

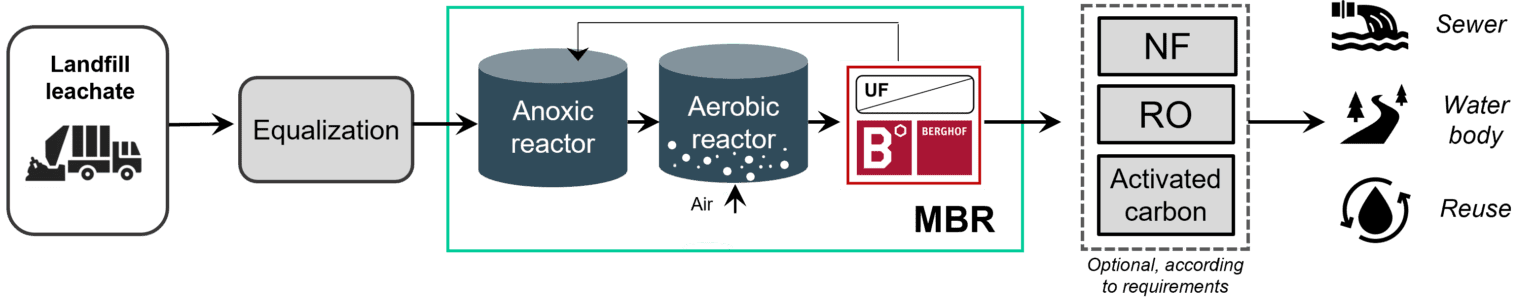

Landfill leachate is treated with the tubular MBR technology. The biological stage combines aerobic and anoxic reactors for removing the significant amount of nitrogenated compounds present in the leachate. The external tubular modules coupled to the biological process produce a free-of-solids permeate that can be discharged to the sewer, or being post-treated with NF, RO or activated carbon for removing the dissolved refractory organic matter and conductivity. By doing so, the effluent can be discharged to water bodies or reused in the landfill site, for irrigation or other uses.

Made in a state-of-the art LEAN-production facility, with highly-trained production personnel and materials of the highest quality.

With 50 years of experience and more than 2.000 project references across the globe, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Bridging the gap between lab-scale testing and manufacturing. Our team of experts gives you the confidence to apply the technology for your specific wastewater challenges.

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting/engineering phase to operational system monitoring.

50 years of experience and more than 2.000 project references across the globe.

A dairy processor in Richland County, Wisconsin needed to find an efficient process to generate electricity and heat from their wastewater and to further treat anaerobic industrial wastewater.

In order to meet the increasing demand, Holland Malt has decided to double its

malting capacity. For this the company needed high-quality permeate to reuse for production.

Our OEM-Partner needed to design a robust and adaptable UF system that could keep up with the high-solid streams and conditions of this demanding process while minimizing OPEX and fouling.

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands