For the high-strength dairy effluents (COD > 10 – 15 g/L) the anaerobic MBR is often the best choice. The Berghof tubular UF is coupled to a simple CSTR digester, allowing the operation with high OLRs (10 kg COD/m3·day) while producing a high-quality effluent. The Berghof membranes ensure the complete retention of the biomass within the anaerobic digester and bring a significant improvement in the digestion process, making it more robust, reducing the footprint, and increasing biogas production. In the dairy industry, Berghof AnMBR offers major advantages over other anaerobic technologies based on granular sludge:

The external tubular MBR for dairy wastewater treatment has numerous advantages over the conventional biological processes and the submerged MBRs:

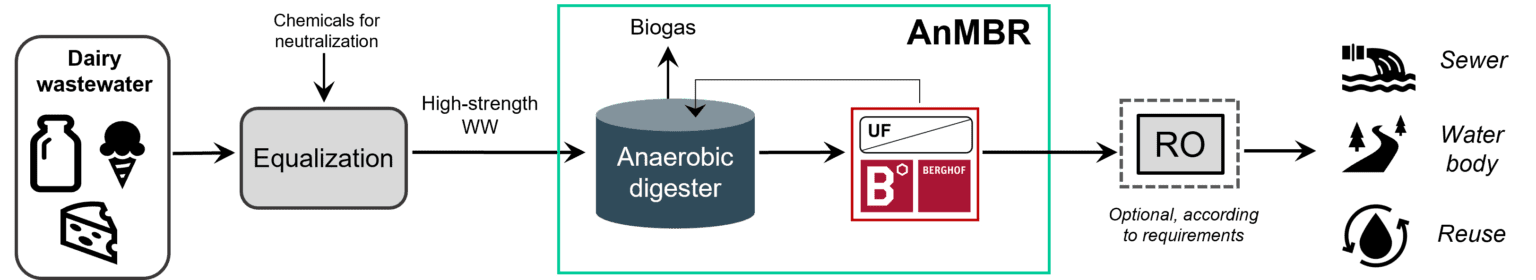

COD removals > 98 – 99% and complete retention of solids, allowing the direct discharge after the AnMBR or the post-treatment with RO if required, for reuse in the dairy facility.

In contrast with the granular anaerobic systems which are known to suffer degranulation under these conditions; this fact deteriorates the effluent quality and leads to decreased efficiency because of the washout of biomass.

As a result of the better effluent quality and the ability to cope with high TSS and FOG, pre-treatment can be simplified and the production of biogas production can be maximized.

In some approaches, aerobic and anaerobic MBRs can be combined in the same installation for treating wastewaters with different organic loads. In this way, when very high and low/medium COD values need to be managed the best performance in terms of operational costs and effluent quality is achieved.

The external tubular MBR for dairy wastewater treatment has numerous advantages over the conventional biological processes and the submerged MBRs:

The high-strength wastewater or by-products like whey are mixed in the equalization tank. Here, chemicals are often required for neutralization, since the use of acid and alkaline products for cleaning and sanitizing results in a highly variable pH.

The tubular anaerobic MBR removes the organic pollutants in a single treatment step, producing renewable energy in form of biogas and high-quality treated water. This effluent can be disposed into the sewer, although in some cases it even fulfills the requirements for water body discharge. Reuse is also possible after a reverse osmosis step.

Made in a state-of-the art LEAN-production facility, with highly-trained production personnel and materials of the highest quality.

With 50 years of experience and more than 2.000 projects worldwide, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Bridging the gap between lab-scale testing and manufacturing. Piloting gives you the confidence to apply the technology for your specific wastewater challenges.

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting and engineering phase to operational system monitoring.

50 years of experience and more than 2.000 project references across the globe.

External AnMBR system in USA for dairy, one of the largest users of wastewater out of all major industries.

External MBR wastewater treatment system for a large malt producer in The Netherlands.

In China, a company manufactures 600K tons of sodium carbonate per year.

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands