MBR

MBR Solutions for Wastewater Treatment

MBR is ideal for the treatment of medium strength industrial wastewater, being the most efficient for removing the organic pollutants and nutrient loads. The UF membranes retain the biomass (MLSS) within the bioreactor, thus producing a superior and consistent quality effluent, free of solids, turbidity and pathogens.

Years of Experiences

- Best Quality Standards

- State-Of-The-Art Production

- Quality Control System

- LEAN Manufacturing

- Highly Professional Team

- Market leader in tubular UF

Minimize short and long-term environmental impact

In an effort to minimize the short and long-term environmental impact, industries across the globe are facing increasing challenges and costs related to wastewater management. As a result, most of the industrial facilities have built their own treatment plants, thus achieving regulatory compliance, avoiding the fees for sewer discharge, and reducing their water footprint by means of water reuse.

The MBR is essentially a high-efficient evolution of the conventional activated sludge process, where the clarifiers are replaced by the tubular UF modules. In this way, significant improvements are achieved: superior effluent quality, higher biodegradation rates, smaller footprint, less sludge production and reuse possibilities. All these features are essential for coping with the stringent discharge quality requirements and the economic benefits of water reuse faced by almost all the industrial sectors.

MBRs remove up to 99% of COD, compared to 90-95% in conventional activated sludge processes. The operation with higher MLSS concentration – even up to 30 g/L – results in minimum footprint requirements and decreased production of excess sludge. The filtrate produced by the membranes is free of solids (TSS < 1 mg/L) and turbidity (< 1 NTU), and presents SDI values lower than 3, optimum for further RO treatment if required.

External Crossflow Filtration Technology

Berghof Membranes specializes in external MBRs that are positioned outside the bioreactor and utilize crossflow velocity to keep the membranes working at optimal conditions. Your benefits:

Less membrane fouling

Long membrane lifespan

Ease of maintenance

Flexible and adaptable

Stable long-term performance

Reliable performance with complex wastewater

Compactness and modularity

Closed system. No odor, VOCs

External crossflow filtration vs. Submerged membrane filtration

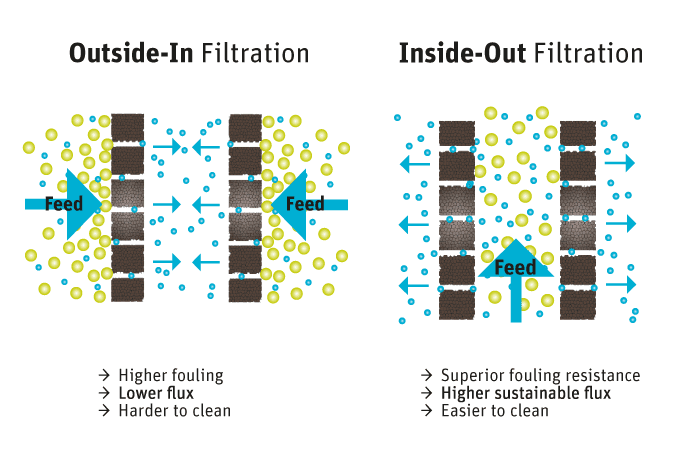

Unlike the outside-in submerged membranes, our inside-out external tubular modules provide higher fluxes with less frequent cleanings and reduced maintenance operations. The cross-flow operation allows operating with higher MLSS and dealing with complex wastewaters, containing FOG, hardness or high levels of recalcitrant matter. The external filtration systems are quickly assembled and do not require complex civil works. The modules are easily accessible for inspection and maintenance, reducing system downtimes to a minimum. Finally, the enclosed filtration system is clean and operator-friendly, with neither odor nor exposure to the wastewater.

Upgrading of existing wastewater treatment facilities

Many industrial facilities are facing the need for upgrading their existing treatment plants. There are a number of reasons pushing the conversion:

- The discharge quality requirements are not fulfilled, due to the increasingly stringent regulations;

- Reusing the treated water becomes cost-efficient, as long as the fresh water cost increases and the discharge fees to municipal sewer raise;

- The increased production leads to the expansion of the facility, and the wastewater treatment plant becomes an hydraulic bottleneck in the production plant.

Under any of these circumstances, the conversion of the existing CASP or SBR processes into MBRs turns out as the most favourable solution, providing significant benefits at both technical and economical sides. By coupling the external tubular UF system to the existing biological reactor the wastewater treatment plant will provide a much better quality treated water, and the capacity of the plant shall be increased up to three times if required. The external MBR system has undoubted advantages for retrofit and conversion:

Plug & Play

CAPEX

Savings on footprint

Existing biological reactor

Presentation MBR wastewater treatment for the food and beverage industry

Presentation

Presentation

Case Studies

Our projects

50 years of experience and more than 2.000 project references across the globe.

AnMBR | Dairy Industry

A dairy processor in Richland County, Wisconsin needed to find an efficient process to generate electricity and heat from their wastewater and to further treat anaerobic industrial wastewater.

MBR | Food & Beverages

In order to meet the increasing demand, Holland Malt has decided to double its

malting capacity. For this the company needed high-quality permeate to reuse for production.

Direct UF | Titanium Recovery

Our OEM-Partner needed to design a robust and adaptable UF system that could keep up with the high-solid streams and conditions of this demanding process while minimizing OPEX and fouling.

Delivering The Best Services

“Unique, customized solutions are the specialty of Berghof Membranes.”

With over 40 years of experience and more than 1500 project references across the globe, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

Tubular UF Membrane Modules

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Membrane Skid systems

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Pilot systems & Lab testing

Bridging the gap between lab-scale testing and manufacturing. This gives you the confidence to apply the technology for your specific wastewater challenges.

B-CARE® Service and Support Program

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting / engineering phase to operational system monitoring.

Think outside the box

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

More than just a membrane supplier

Contact Berghof Membranes

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands