Technology

Think Outside the Box

The external principle

We at Berghof Membranes believe in external side stream membrane filtration and it is the passion that drives us to “think outside the box” of membrane technology for wastewater treatment. In tubular membrane filtration systems are placed OUTSIDE the feed tank or bioreactor, thereby resolving the inherent problems with many applied technologies.

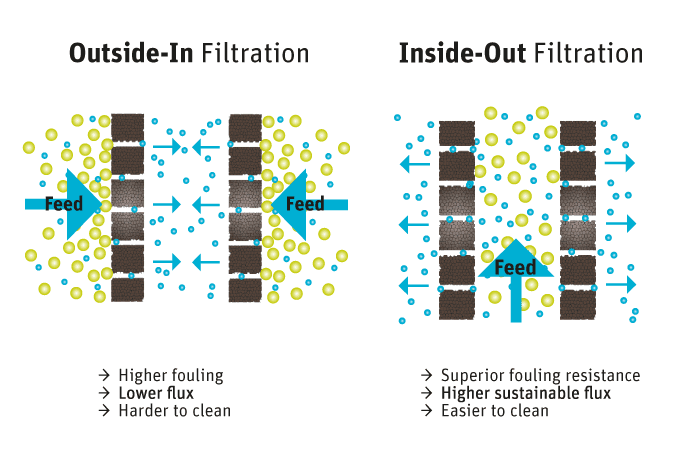

To drastically minimize membrane fouling and clogging, Berghof Membranes developed its line of robust external membrane systems based on INSIDE-OUT crossflow filtration. This means superb fouling resistance and control, ideal for the separation and filtration of challenging industrial effluent and wastewater. As result, our robust filtration systems enable operators to sustain higher flux rates with less frequent cleanings and reduced maintenance.

External tubular membrane filtration present significant advantages for industrial treatment plants which are subject to varying processes- and waste streams. The ability to control crossflow velocity, results in a significant reduction of energy consumption, fouling potential and operating costs.

The external configuration

To prevent fouling and clogging, Berghof Membranes developed its robust tubular UF membranes based on cross-flow filtration technology (inside-out filtration), resulting in more fouling-resistant membranes that are ideal for the separation and filtration of challenging industrial effluent and wastewater.

Unlike dead-end filtration (outside-in filtration), as seen with conventional submerged membrane technology, crossflow filtration allows operators to sustain higher flux rates with less frequent cleanings and reduced maintenance.

Tubular UF membranes are also available in back-washable configurations that require less chemical usage and system downtime, thus extending the life of the membrane.

Why External Membrane Filtration in Wastewater Treatment:

Berghof Membranes developed the B-SMART® intelligent software platform to further assist our OEM partners in offering unique and advanced solutions to their customers.

- Easier operation, maintenance and replacement of modules

- Higher flux rates (50-150 LMH)

- Lower fouling potential

- Less chemical usage due to extended cleaning periods

- Modular “plug-and-play” design

- Quick commissioning and superior flexibility

- Zero odor emissions

Operator Benefits

External Membrane Filtration

Case Studies

Our projects

50 years of experience and more than 2.000 project references across the globe.

AnMBR | Dairy Industry

A dairy processor in Richland County, Wisconsin needed to find an efficient process to generate electricity and heat from their wastewater and to further treat anaerobic industrial wastewater.

MBR | Food & Beverages

In order to meet the increasing demand, Holland Malt has decided to double its

malting capacity. For this the company needed high-quality permeate to reuse for production.

Direct UF | Titanium Recovery

Our OEM-Partner needed to design a robust and adaptable UF system that could keep up with the high-solid streams and conditions of this demanding process while minimizing OPEX and fouling.

Manufactured in Germany

Made in a state-of-the art LEAN-production facility, with highly-trained production personnel and materials of the highest quality.

With 50 years of experience and more than 2.000 project references across the globe, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

Tubular UF Membrane Modules

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Membrane Skid systems

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Pilot systems & Lab testing

Bridging the gap between lab-scale testing and manufacturing. Our team of experts gives you the confidence to apply the technology for your specific wastewater challenges.

B-CARE® Service and Support

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting/engineering phase to operational system monitoring.

Think outside the box

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

More than just a membrane supplier

Contact Berghof Membranes

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands