In order to meet stringent water reuse standards, pharma and chemical industries are looking for finding a cost-effective solution to treat the reverse osmosis (RO) concentrate and improving the overall RO system recovery. Nowadays that zero liquid discharge (ZLD) is attracting more and more attention, the combination of tubular UF with chemical precipitation processes turns up as a successful and efficient solution for brine recovery.

Cost-efficient chemical process: the implementation of tubular UF instead of the conventional clarifiers allows reducing the chemical dosing and avoids the use of flocculants.

Tubular UF removes all the solids and colloids coming from the previous precipitation process. UF permeate is directed to a post-RO system within the ZLD strategy, reaching a minimum discharge and getting a maximum reuse of water.

Berghof UF systems replace the clarifiers and posterior microfilters. The footprint required is minimized.

When precipitation at high pH conditions is required, the Berghof CR membranes provide a robust solution, with proven long-term performance and minimum maintenance and replacement costs.

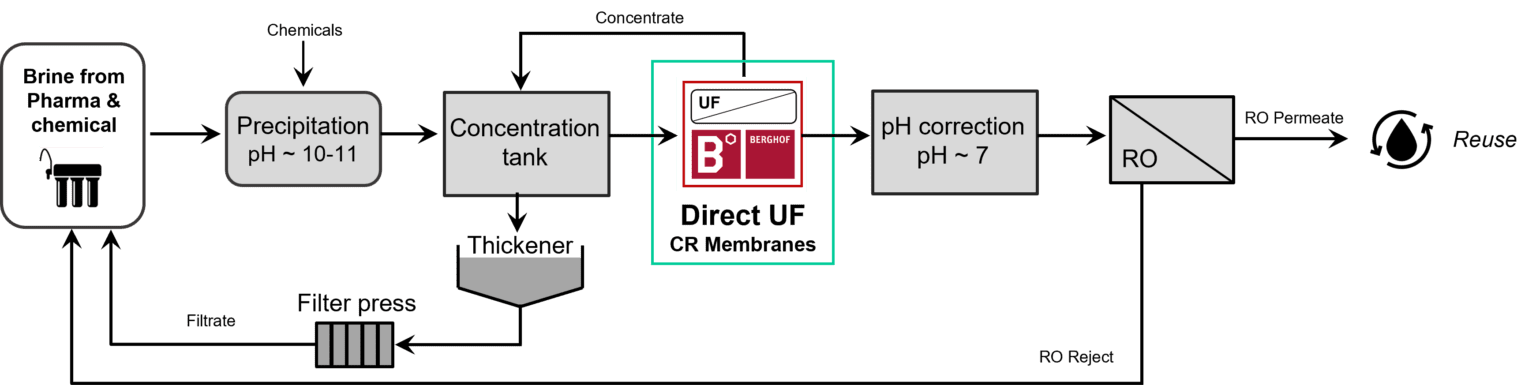

The brine generated in the production of high-quality process water is recovered in a process combining the chemical precipitation and the tubular ultrafiltration. The first precipitation step is carried out with the addition of chemicals (NaOH, Na2CO3…) for increasing the pH and promoting the precipitation of ionic pollutants (hardness, sulphates…).

The tubular modules with chemical resistant membranes are connected to a concentration tank, producing a permeate with greatly reduced dissolved compounds and a reject containing a high concentration of precipitated species. This reject is dewatered in a filter press. The UF permeate, after neutralization, is treated in a second RO step. The ZLD is therefore achieved: the high-quality RO permeate is reused, and the RO reject returns to the head of the brine recovery process.

Kunshan Zhong Yan Company, located in Kunshan City in China’s Jiangsu province, manufactures 600,000 tons of sodium carbonate (also known as “soda ash”) per year. Sodium carbonate serves multiple purposes in both domestic and industrial applications – widely used as a water softener, as a component in the manufacture of glass, a common additive used in swimming pools, and as an ingredient in certain foods, just to name a few.

Made in a state-of-the art LEAN-production facility, with highly-trained production personnel and materials of the highest quality.

With 50 years of experience and more than 2.000 project references across the globe, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Bridging the gap between lab-scale testing and manufacturing. Our team of experts gives you the confidence to apply the technology for your specific wastewater challenges.

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting/engineering phase to operational system monitoring.

50 years of experience and more than 2.000 project references across the globe.

A dairy processor in Richland County, Wisconsin needed to find an efficient process to generate electricity and heat from their wastewater and to further treat anaerobic industrial wastewater.

In order to meet the increasing demand, Holland Malt has decided to double its

malting capacity. For this the company needed high-quality permeate to reuse for production.

Our OEM-Partner needed to design a robust and adaptable UF system that could keep up with the high-solid streams and conditions of this demanding process while minimizing OPEX and fouling.

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands