The textile industry uses different dyes and pigments for coloring the final fabrics manufactured. The main difference between both is essential that dyes are soluble in water and pigments are not. And therefore, tubular UF membranes are able to remove pigments in those specific streams coming from the dying processes. By doing this before they are mixed with the rest of the wastewater coming from further processing steps, the whole treatment can be greatly simplified.

As an example, we find the so-called indigo blue dye used for denim, where Berghof tubular UF removes up to 90% color and > 99% turbidity. In this approach, the Berghof tubular UF membranes are applied as a solely direct filtration treatment step. The ability to cope with high suspended solids concentration, together with the cross-flow operation that minimizes the fouling, allows operating the system with high fluxes, minimum reject, and definite stability. The permeate obtained is clear, free of pigments and turbidity. The reject stream can even be recyclable within the dying process.

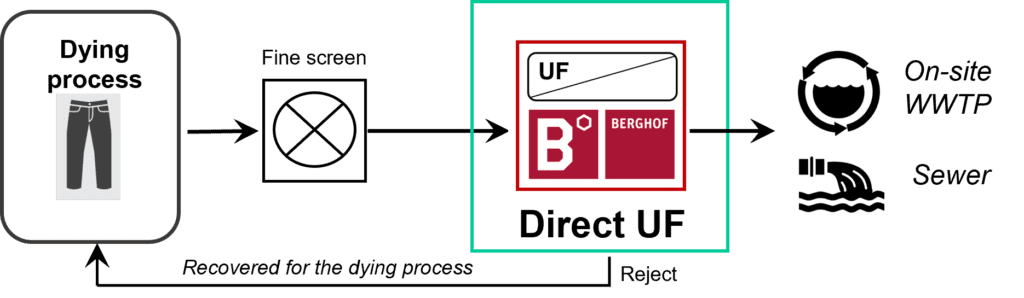

The dying processes in the textile industry generate separated waste streams containing a significant amount of residual dye products. After the fine screening to remove the fibers, this stream is directed to the tubular ultrafiltration membranes. Here, a reject with a high dye concentration is produced: it can be recovered for the dying process. The permeate is free of dyes, solids and turbidity; it can be mixed with additional waste streams generated in the textile facilities and directed to the on-site treatment plant. Alternatively, it can be discharged to the public sewer in the case that the quality fulfills the local standards.

Made in a state-of-the art LEAN-production facility, with highly-trained production personnel and materials of the highest quality.

With 50 years of experience and more than 2.000 projects worldwide, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Bridging the gap between lab-scale testing and manufacturing. Piloting gives you the confidence to apply the technology for your specific wastewater challenges.

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting and engineering phase to operational system monitoring.

50 years of experience and more than 2.000 project references across the globe.

A dairy processor in Richland County, Wisconsin needed to find an efficient process to generate electricity and heat from their wastewater and to further treat anaerobic industrial wastewater.

In order to meet the increasing demand, Holland Malt has decided to double its

malting capacity. For this the company needed high-quality permeate to reuse for production.

Our OEM-Partner needed to design a robust and adaptable UF system that could keep up with the high-solid streams and conditions of this demanding process while minimizing OPEX and fouling.

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands