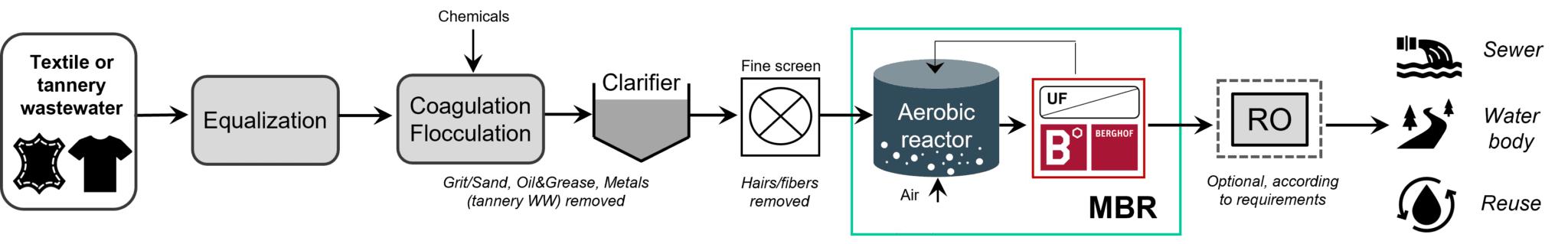

For textile and tannery wastewater, the MBR guarantees a high-quality effluent: free of solids and turbidity, and with lower COD, BOD and color as compared with the conventional biological treatment. There are different types of dies used and they behave differently during the biological treatment. Especially the synthetic dies are characterized by being refractory, with poor biodegradability. Previous experience demonstrates that the MBR removes them better (> 30%) due to the long sludge age and the growth of specialized biomass.

Apart from this, when further color removal is required for discharge or reuse, the great advantage of the MBR is that it produces a high-quality effluent with SDI < 3, that can be directly fed to a NF or RO post-treatment and allows these systems to operate with maximized recovery.

The treatment of textile and tannery wastewater is addressed with MBR biological treatment. Before the MBR, certain pre-treatments are typically applied. Especially in the case of tannery wastewater, oil and grease separation and chemical precipitation for metals removal are implemented. Due to the presence of hairs and fibers, a fine screening is also required. The MBR effluent fully complies with the requirements for discharge into sewer or a receiving water body. Alternatively, it can be reused, either directly or after removing the dissolved compounds with reverse osmosis.

A company in India services the wastewater treatment needs of its 130+ member tanneries via a common effluent treatment plant (CETP). Due to the volume of wastewater generated from the tannery industry and the need to reduce discharge levels, the company needed a more effective MBR system to replace the existing low energy aerated MBR.

Made in a state-of-the art LEAN-production facility, with highly-trained production personnel and materials of the highest quality.

With 50 years of experience and more than 2.000 projects worldwide, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Bridging the gap between lab-scale testing and manufacturing. Piloting gives you the confidence to apply the technology for your specific wastewater challenges.

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting and engineering phase to operational system monitoring.

50 years of experience and more than 2.000 project references across the globe.

A dairy processor in Richland County, Wisconsin needed to find an efficient process to generate electricity and heat from their wastewater and to further treat anaerobic industrial wastewater.

In order to meet the increasing demand, Holland Malt has decided to double its

malting capacity. For this the company needed high-quality permeate to reuse for production.

Our OEM-Partner needed to design a robust and adaptable UF system that could keep up with the high-solid streams and conditions of this demanding process while minimizing OPEX and fouling.

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands