Some waste streams contain high-value products such as metals. Metal recovery processes are attracting increasing attention, as a way for gaining profitability while reducing the environmental footprint.

The metal recovery process involves different technologies, depending on the type of metal, characteristics of wastewater, solid/dissolved state, etc. In some cases, complex chemical and ion-exchange processes are involved in the global process. In other cases, tubular UF by Berghof Membranes is applied as a unique step for separating the particulate metals (including sub-micron scale). Finally, the polymer-enhanced ultrafiltration is a breakthrough approach for the recovery of metals: by adding a soluble polymer able of binding polyvalent cations, a metal-polymer complex is formed, which is retained by the UF membranes.

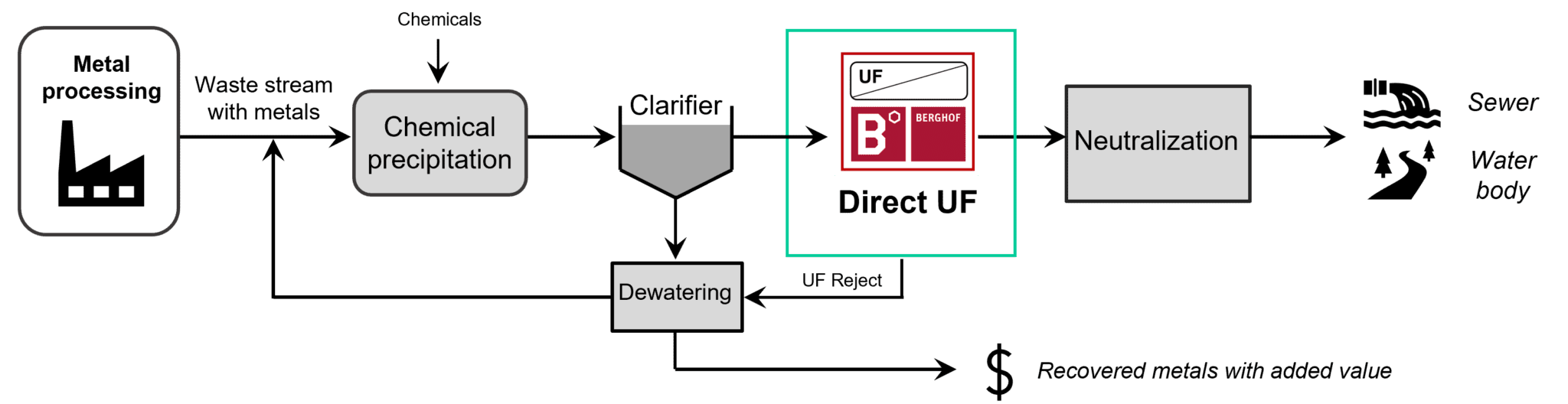

Metal processing generates waste streams containing valuable materials, in the form of small-size particles or as dissolved ions. In the latter case, a chemical precipitation process is applied before the tubular ultrafiltration system. Here, the suspended matter is retained and concentrated. The UF reject is afterwards dewatered for recovering the added-value materials. The UF permeate can be disposed to the sewer together with other waste streams generated in the facilities, or it can be discharged to water bodies in cases where the quality parameters are adequate.

For a factory in the mid-western United States specialized in the recovery of titanium from waste streams our OEM-Partner Belmar Technologies needed to design a robust and adaptable ultrafiltration system. A system that could keep up with the high-solid streams and conditions of this demanding process while minimizing energy consumption, membrane fouling and clogging.

The challenge:

Made in a state-of-the art LEAN-production facility, with highly-trained production personnel and materials of the highest quality.

With 50 years of experience and more than 2.000 project references across the globe, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Bridging the gap between lab-scale testing and manufacturing. Our team of experts gives you the confidence to apply the technology for your specific wastewater challenges.

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting/engineering phase to operational system monitoring.

50 years of experience and more than 2.000 project references across the globe.

A dairy processor in Richland County, Wisconsin needed to find an efficient process to generate electricity and heat from their wastewater and to further treat anaerobic industrial wastewater.

In order to meet the increasing demand, Holland Malt has decided to double its

malting capacity. For this the company needed high-quality permeate to reuse for production.

Our OEM-Partner needed to design a robust and adaptable UF system that could keep up with the high-solid streams and conditions of this demanding process while minimizing OPEX and fouling.

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands