The external tubular MBR brings considerable benefits in the treatment of pharmaceutical and chemical effluents. With many references in operation all over the world, Berghof membranes have been proven to provide significant advantages over alternative technologies:

The external tubular MBR for dairy wastewater treatment has numerous advantages over the conventional biological processes and the submerged MBRs:

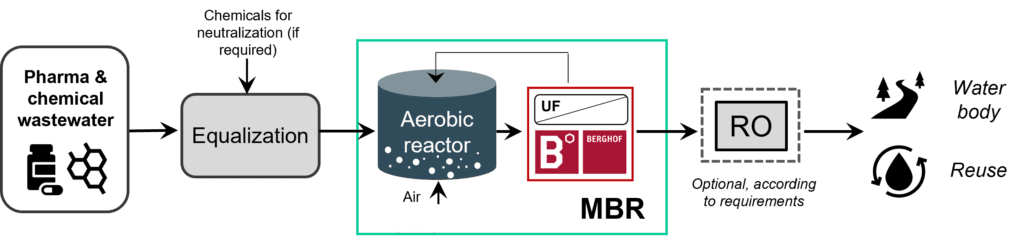

Increased bioprocess performance. Difficult to biodegrade compounds found in pharma and chemical wastewaters are efficiently handled. The high SRT and the specialized biomass allow a >50% removal when compared with the conventional treatment methods.

Superior effluent quality. MBR effluent is free of solids, colloids, and turbidity. The SDI is lower than 3, meaning that it can be directly fed to a reverse osmosis system in the case that high-quality reusable water is needed for the production of chemicals and pharmaceuticals.

Berghof UF systems provide the most compact design, which can be easily customized to the available space. Retrofitting of existing plants is easy and quick. The plug&play systems allow an improved performance with minimum system downtime and civil works.

External tubular UF provides more flexibility and robustness against variabilities in the pharma and chemical wastewater characteristics. Thanks to the several fouling control mechanisms external tubular membranes are much less affected in shock loads or toxic/inhibition scenarios, which are known to affect the performance of submerged membranes.

The waste streams generated in the different dairy operations are mixed in the equalization tank. Here, chemicals are often required for neutralization, since the use of acid and alkaline products for cleaning and sanitizing results in a highly variable pH.

For certain dairy products such as butter, the oil concentration can be significant: under these circumstances, a DAF pre-treatment is typically applied.

The tubular MBR is the core process for treating the low-medium strength dairy wastewater. The biological treatment comprises anoxic and aerobic stages when nitrogen removal is required. If not, only the aerated bioreactor is installed for removing the organic pollutants.

The MBR effluent fully complies with the requirements for discharge into a receiving water body. Alternatively, it can be reused in non-contact applications (steam generation, cooling towers…). In those reuses that require deionized water, a final reverse osmosis is implemented.

Made in a state-of-the art LEAN-production facility, with highly-trained production personnel and materials of the highest quality.

With 50 years of experience and more than 2.000 projects worldwide, Berghof Membranes is the leading manufacturer of high quality tubular membranes.

To prevent fouling and clogging, Berghof Membranes developed its line of robust tubular UF (ultrafiltration) membrane modules based on inside-out crossflow filtration.

Berghof Membranes developed B-SMART®, a customizable external membrane filtration system that can be designed with various features and functionalities.

Bridging the gap between lab-scale testing and manufacturing. Piloting gives you the confidence to apply the technology for your specific wastewater challenges.

The B-CARE® program is an end-to-end comprehensive program developed to support our OEM partners from the piloting and engineering phase to operational system monitoring.

50 years of experience and more than 2.000 project references across the globe.

A dairy processor in Richland County, Wisconsin needed to find an efficient process to generate electricity and heat from their wastewater and to further treat anaerobic industrial wastewater.

In order to meet the increasing demand, Holland Malt has decided to double its

malting capacity. For this the company needed high-quality permeate to reuse for production.

Our OEM-Partner needed to design a robust and adaptable UF system that could keep up with the high-solid streams and conditions of this demanding process while minimizing OPEX and fouling.

When it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Get in touch today

International Sales Office:

Agora 4, 8934 CJ Leeuwarden,

The Netherlands